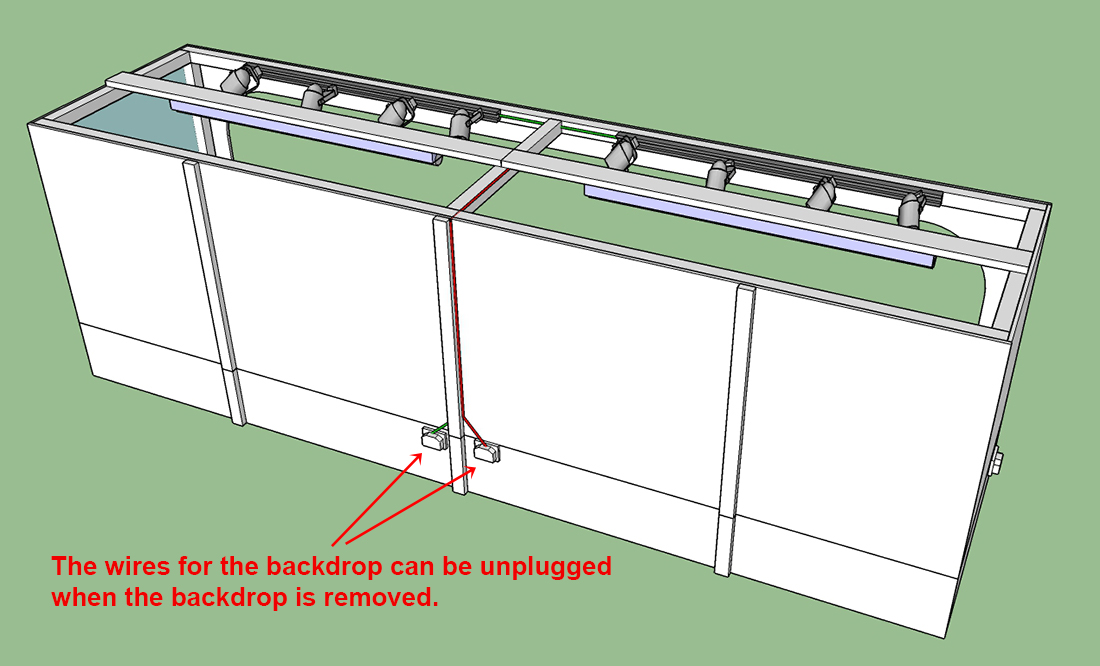

I didn’t keep any images of The Depot module construction so instead I’ve added those belonging to the Town. I made several refinements but the underlying concept is the same: a removable backdrop that sits upon a base:

by Kumar Desai

I didn’t keep any images of The Depot module construction so instead I’ve added those belonging to the Town. I made several refinements but the underlying concept is the same: a removable backdrop that sits upon a base:

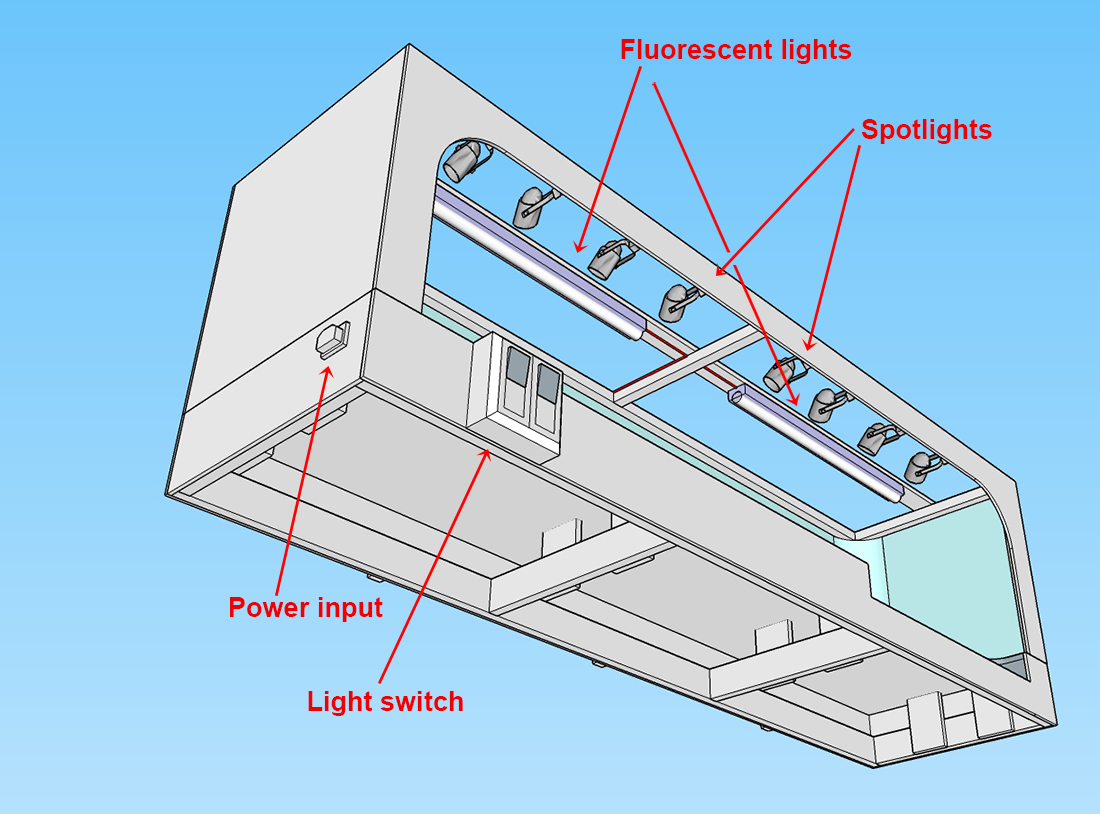

The layout is being housed in a purpose-built cabinet. The cabinet is designed to hold another module on the top shelf and a series of dioramas on the bottom shelf.

Opting to build a series of modules depicting the branch line I always intended rolling stock to be able to move between them. The only issue was how to do it. I don’t have space for staging so I decided to build a fixture called a ‘cassette’ to store, assemble and move trains between modules. I first read about cassettes in one of Iain Rice’s books on small layouts and always thought that they were good way to save space and store trains. The underlying concept is of two aluminium corner bars mounted on a wooden deck which join to the layout at a docking point. The three main components are a cassette, a dock and a cradle. Here are some images of the design and construction process:

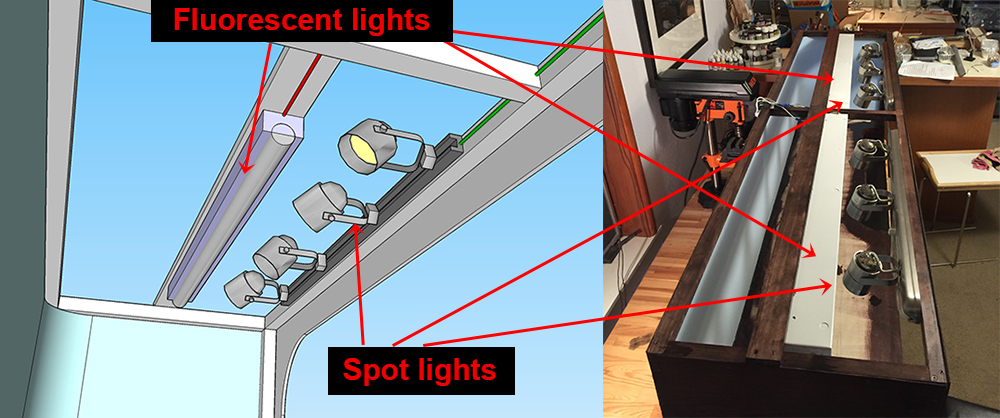

The lighting consists of two fluorescent lights and two sets of spotlights. The drawings below show the lighting for the new module but are used in a similar way on The Depot.

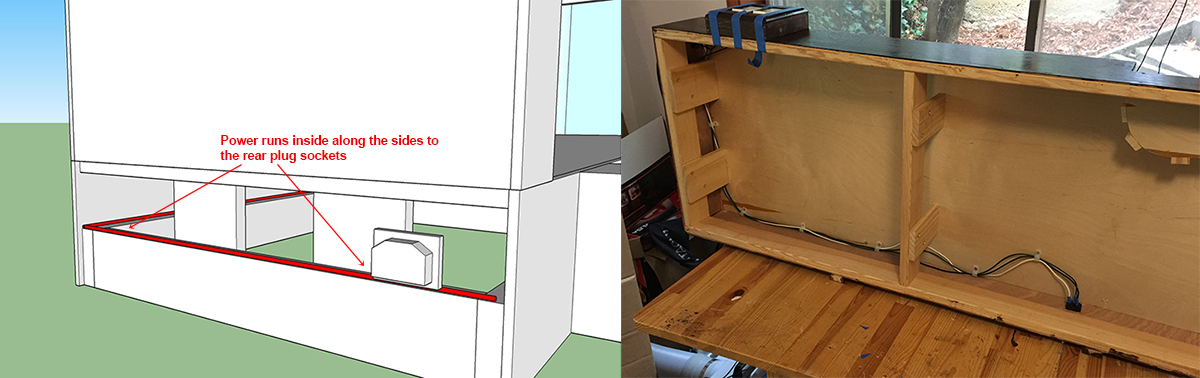

On the inside I ran the cables along the sides to two plug sockets at the back.

Power runs to the lights from the back from these two plugs. They can be detached when I need to remove the backdrop. At the top I used terminal blocks to get power to the individual lights.

There are two sets of lights. Fluorescent lights which provide a consistent overall cast and spotlights which focus a warm light on specific areas. The spotlights have their own dimmer.